Testing Process

A fully traceable quality control system ensures zero-defect delivery

1

Raw material entry inspection

2

Production process monitoring

3

Final product inspection

4

Value-added services

Raw material entry inspection

- Spectroscopy analyzer (Olympus XRF) for detecting substrate composition (C, Si, Mn, P, S content)

- Cold rolled coil hardness test (Rockwell/Vickers hardness tester)

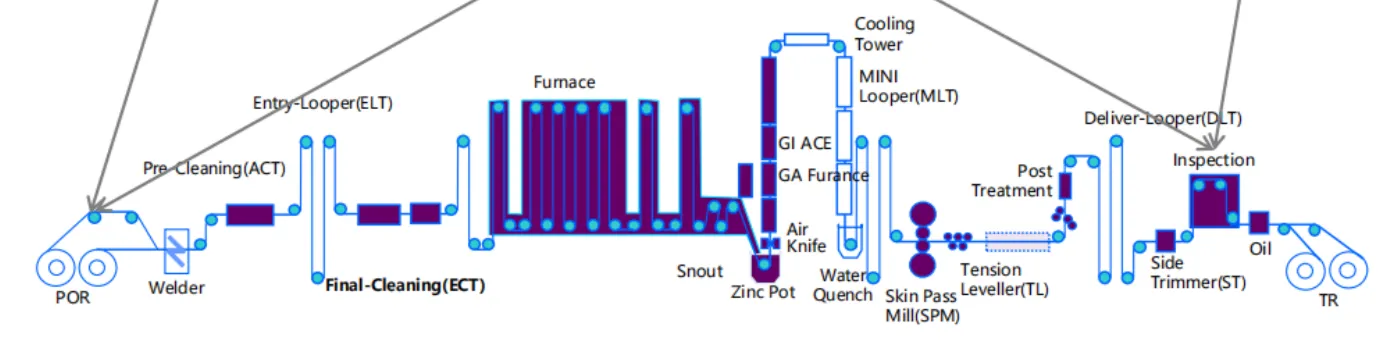

Production process monitoring

- Continuous coating thickness gauge (X-ray fluorescence) continuously monitors the weight of the zinc layer (g/m²)

- Online surface defect detection system (AI visual scanning for pinholes/scratches)

Final product inspection

- Mechanical properties: Tested by universal testing machine for tensile strength (≥300MPa), yield strength, elongation (≥18%)

- Coating adhesion: T-bend test (0T - 3T grades) & salt spray test (galvannealed steel > 500 hours)

- Dimension tolerance: Laser thickness gauge(±0.05mm) & Flatness (≤3I-units)

Value-added services

- Support on-site witnessing tests by institutions such as SGS/BV

- Provide english version of test reports for each batch (including sample photos and data charts)

- Customized additional tests (such as cupping test, metallographic analysis) are available

Quality Control

Check the materials for opening the package on the side

Check the materials of the upper volume on the entry side

Vertical inspection of the products on the output side

Inspection of the product level on the output side

1. Zinc coating quantity measuring instrument

2. Surface defect detector

3. Thickness gauge

4. Width measuring device

5. Tablet press

Laboratory Testing Capability

Mechanical property

| Analysis item | Device name |

| Sample processing | Shearing machine,sample punch press,data processing center |

| Elongation test | Electronic universal material testing machine |

| Baking hardening test | Oil bath pan |

| Bending test | Bending tester |

| Coating adhesion test | Lock forming |

| Delta test | XRD |

| Coating weight test | XRF |

| Hardness test | Rockwell hardness tester |

| Surface roughness test | Surface roughometer |

| Simulated stamping test | Mini press |

| Microstructure testing | Metallographic microscope,scanning electron microscope,eds |

| Salt spray test | Salt spray tester |

| Oil film thickness test | Ink thickness gauge |

| Color compare test | Colorimeter |

Test equipment

Scanning electron microscope(SEM)

X-ray diffractometer

Tensile testing machine

Chemical analysis

| Analysis Item | Device Name |

| Water quality analysis | ICP |

| Water quality analysis | UV spectrophotometer |

| COD | COD analyzer |

| PH | PH meter |

| Conductivity test | Conductivity meter |

| Turbidity test | Turbidity meter |

| Suspended solids test | Electric heating blower drying oven, vacuum pump |

| Sample preparation | Electronic scales |

| Density determination | Densimeter |

| BOD | Electric heating constant temperature incubator, dissolved oxygen meter |

| Inspection of the surface of steel sheets | SDD |

Quality Standards & Certifications

Strictly implement international standard

Galvannealed steel: ASTM A653 / EN 10346

Hot-dip galvanized steel: ISO 1461 / ASTM A123

Cold rolled steel: JIS G3141 / ASTM A1008

System certification: ISO 9001, ISO 14001

Compliant with RoHS and REACH environmental directives.

Material Selection Guide

Precisely match scenarios according to product features

Galvannealed steel

Core advantageUltra-high corrosion resistance/excellent welding performance

Recommended application scenariosPhotovoltaic brackets/car chassis/coastal buildings

Key parameter guidanceCoating≥80g/m², salt spray test > 500h

Hot-dip galvanized steel

Core advantage

Economical protection/anti-mechanical damage

Recommended application scenarios

Steel structure factory buildings/agricultural greenhouses/cable trays

Key parameter guidance

Coating Z80-Z275, yield strength ≥120MPa

Cold rolled steel

Core advantage

Smooth surface/precisely formed

Recommended application scenarios

Home appliance panels/chassis cabinets/precision stamping parts

Key parameter guidance

Surface grade FB (high-grade finishing), thickness tolerance ±0.1mm

Contact Us

E-mail: partner@rosensteelga.com

Tel: +86-27-86615388

WhatsApp: +86 177 6252 7953

WeChat:Rosen17762527953

Add.: No. 1, 30th Floor, Building 1, Fuxing Huiyu Waterfront International, Sanjiao Road Village, Xujiapeng Street, Wuchang District, Wuhan City, Hubei Province,P.R.China